Description

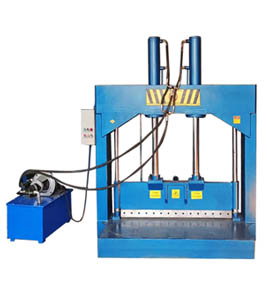

The Double-Acting Cylinders Hydraulic Guillotine Bale Cutter is a powerful, high-volume and precision industrial rubber cutting machine, Different from conventional single-acting systems hydraulic bale cutter,

this double-acting cylinder model is equipped with a dual-action hydraulic system that drives precisely control both the downward and upward strokes.

With its advanced hydraulic system and robust structure, this machine offers unmatched control, efficiency, and safety. It directly lead to faster speed cutting cycles and smoother, more reliable operation, which make it ideal for rubber, tire, plastic, textiles, and composite bales , compounding industries, and other dense materials

Built on a heavy welded steel frame with rigid reinforcement, the industrial guillotine bale cutter machine ensures minimum deflection under load. The guillotine knife or blade is guided via hardened guideways to maintain alignment and reduce blade wear.

Specification

| Type | Width (mm) | Stroke (mm) | Diameter of the piston (mm) | Time Taken by the Stroke (second) | Power (KW) | Overall Dimension (LxWxH) | Weight (kg) |

| SMP-8 | 660 | 680 | 150 | 16~25 | 5.5 | 1900×720×2580 | 1500 |

| SMP-10 | 1000 | 1000 | 150 | 10~16 | 7.5 | 2240×720×2580 | 1800 |

| SMP-12 | 1000 | 1200 | 150 | 10~16 | 7.5 | 2540×750×2880 | 2000 |

Technical Features

Design and Build Quality

Such hydraulic bale cutter is constructed by a high-quality rigid steel frame, precision guide rails, and a replaceable hardened blade.

Hydraulic Power System and Pressure Capacity

Double-acting cylinders deliver high cutting forces ranging from 40 to 160 tons, which depend on the model.

Control Options and Automation Capabilities

Available in both manual and automated style equipped with PLC control, programmable stroke limits, and optional safety interlocks.

How Does Rubber Bale Cutter Work?

The high-precision hydraulic-powered rubber bale cutter are used to cut rubber into pieces as per speicific needs. The rubber bales or block can be fed through the machine. These rubber piece cut travels through the rubbe bale cutter machine which ensures smooth movement.

1. Check blade is in the up position.

2. Open the gate.

3. Place slab of rubber along the cutting edge.

4. Leave the cage area and close the gate.

5. Press the cut button to lower the blade to cut the rubber slab.

6. Blade rises after the cut sequence; wait until the blade is fully up.

7. Open the gate to remove the cut pieces.

8. Repeat the cycle.

Benefits of Using Automatic Rubber Bale Cutters

* Improved Safety – Aucomatic control, no manual inteference to cut with knives or wires; reducing risk of injury.

* Higher Efficiency – Cuts large rubber bales within seconds, boosting productivity.

* Consistent Bale Size – Uniformly cut pieces ensure stable mixing and weighing process.

* Reduced Labor Intensity – Fully automatic cycle minimizes operator fatigue.

* Long Service Life – Durable hydraulic components and cutting structure for long-term industrial operation.

* Clean Work Environment – Neat cutting reduces rubber dust and waste.

A Wide Of Application

The Simptek Rubber Bale Cutter is very flexible and is is used for cutting all kinds of large sized natural rubber or synthetic rubber products, such as large plastic tubes, film, rubber lumps, and sheet materials , it is also very applicable for other plastic ,polymer,silicone including:Rubber product manufacturing plants

Rubber product manufacturing plants

Tire production facilities

Rubber recycling companies

Rubber compound and mixing plants

Silicone,Slicing type

Nitrile Bale

NBR,SBR

FKM

CR, HNBR, ACM,EPDM

EVA

Reviews

There are no reviews yet.