In the world of manufacturing and research, effective mixing is a fundamental process, and the choice of mixing equipment can significantly impact the quality and efficiency of the end product. Lab kneader machines, also known as kneading machines, are one category of mixing equipment often used in laboratories and various industries. But how do they compare to other mixing equipment like planetary mixers, twin-screw extruders, or ribbon blenders? Let’s explore the differences and advantages of lab kneader machines in comparison to their counterparts.

Lab Kneader Machines

1. Kneading Action: Lab kneader machines are specifically designed for kneading and mixing high-viscosity materials. They use a set of counter-rotating blades, typically Z-shaped or Sigma-shaped, to create a strong shearing and kneading action. This action is ideal for materials that require thorough mixing and dispersion, such as adhesives, rubber compounds, and high-consistency rubber.

2. Temperature Control: Lab kneader machines often come equipped with temperature control systems, making them suitable for materials that require precise temperature management during the mixing process. This is particularly important in industries like pharmaceuticals, where temperature-sensitive compounds are involved.

3. Consistency: Lab kneader machines are renowned for producing highly consistent and homogeneous mixtures, a crucial requirement in many industries, including food, pharmaceuticals, and cosmetics.

Planetary Mixers

1. Versatility: Planetary mixers offer versatility and are suitable for a wide range of materials, including low to medium viscosity substances. They use a planetary motion (a rotating blade that moves on its axis while orbiting the mixing bowl) to create thorough mixing.

2. Speed Control: They are known for their ability to control mixing speed effectively, making them suitable for delicate operations like blending powders and creams.

3. Batch Size: Planetary mixers are often used for smaller batch sizes and can be a good choice for research and development purposes.

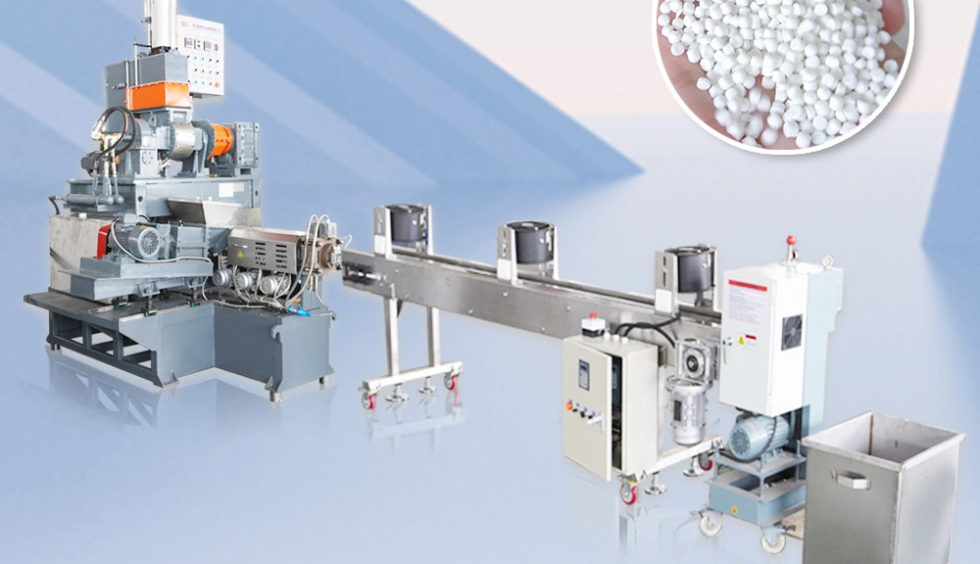

Twin-Screw Extruders

1. Continuous Operation: Twin-screw extruders are designed for continuous mixing and extrusion processes. They are ideal for materials that need constant processing.

2. High Throughput: They offer high throughput capabilities, making them suitable for industries where large volumes of materials need to be processed continuously, such as plastic compounding.

3. Screw Configuration: The configuration of the screws can be adjusted for various mixing and extrusion requirements.

Ribbon Blenders

1. Low Shear: Ribbon blenders are known for their gentle blending action. They are ideal for mixing dry, free-flowing materials like powders and granules.

2. Batch Size: They can handle larger batch sizes, making them suitable for industries that require bulk material blending, like the chemical industry.

3. Simplicity: Ribbon blenders are easy to operate and maintain, making them a cost-effective choice for many applications.

Comparative Analysis

When comparing lab kneader machines to other mixing equipment, it’s essential to consider the specific requirements of your application:

- Material Viscosity: Lab kneader machines excel in high-viscosity applications, whereas planetary mixers are more versatile, suitable for low to medium viscosity materials.

- Consistency: Lab kneader machines are unmatched in producing consistent and homogeneous mixtures, making them suitable for industries where product quality is paramount.

- Continuous vs. Batch Processing: If your operation requires continuous processing, twin-screw extruders may be a better choice, while ribbon blenders are excellent for batch processing.

- Temperature Sensitivity: For temperature-sensitive materials, lab kneader machines with precise temperature control are an advantage.

- Versatility: Planetary mixers offer versatility, especially in research and development settings where different materials are tested.

In conclusion, the choice between lab kneader machines and other mixing equipment depends on the specific needs of your application. Each type of equipment has its strengths, and by understanding these differences, you can make an informed decision to ensure the best results for your mixing processes. Consider the material type, viscosity, batch size, and other factors to select the most suitable mixing equipment for your operation.

When in doubt, consulting with mixing equipment experts such as Lab Kneaders team can provide valuable insights and guidance in selecting the right equipment for your specific requirements.