Description

The silicone mixing machine is suitable for mixing rubber, synthetic rubber, plastic ,polymer ,color masterbatch ,E.V.A. or P.V.C., etc. It is used for Extruder, Calender, Hot Press, or other processing machinery to make Rubber or Plastic products.

The rubber mixing machine mainly comprises a body-shaped frame, frame, roller, transmission gear, gear reducer, motor, and other parts. It is specially designed for bearing heavy loads under extreme working conditions; the lab scale two roll mixing mill is suitable for polymers such as rubber and plastic industry mixing process.

This lab open mixing rubber mill is mainly used for mixing silica gel and rubber equipment. It has fine structure, safety and convenience, broad applicability, and high efficiency.

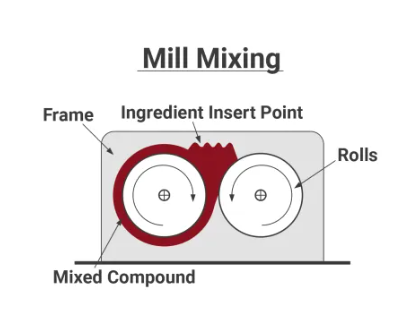

The roller is made of chilled cast iron, hollow, and filled with water but a water system. Its front roller is driven by a pair of speed ratio gears installed at the left end of the roller, while the rear roller is driven to rotate by the transmission gear. Thus, the two rolls would rotate at different speeds in relative directions, mixing the material well.

Mixing machines for silicone and other chemicals are essential for manufacturing products that require high consistency and viscosity. Mixing mill products are designed specifically for this purpose and are the perfect choice for anyone looking to produce high-quality liquid silicone rubber.

This versatile machine is perfect for high and low viscosity mixers, making it the perfect choice for liquid silicone rubber production. Additionally, our mixer can also be used for other chemical production, such as paint, chewing gum, ink, silicone sealant, and more.

How Does a Simptek Laboratory Dispersion Kneader Work?

This lab dispersion kneader is specially designed for mixing a variety of materials ranging from low viscosity adhesive to high viscosity polymers with various additives, such as fillers, plasticizers, and vulcanizing agents. The laboratory kneader feature with small volume, and lower power consumption,it is a high-performance mixing device specially used for for formulation research and small-scale manufacturing.

The dispersion kneader has two blades that rotate toward side to side to cut, mix and blend materials applying different speeds and shear force,which accordingly provide excellent cross mixing of all raw materials.

Steps in the Rubber Mixing Process

1. Introduction of the Polymer

The rubber mixing process begin from the introduction of the polymer, the basic structure of rubber compounding. The choice of polymer material contribute to the foundation for the material’s performance and dictates its inherent characteristics.

2. Sequenced Addition of Ingredients

While the polymer typically has the largest impact on the characteristics, additional ingredients are added would determine its features ,including curing and processing performance, consideration of production cost , hue designation, anti-degradation, and many other . This may be fillers, plasticizers, curing agents, accelerators, etc.

3. Achieving Homogeneity in the Compound

The ultimate goal is to achieve thorough homogeneity. Through well-mixed and blended of all ingredients ,it would create a uniform and consistent rubber compound. A homogeneous rubber compound ensures uniform characteristics throughout production processing, curing and the final application of finished rubber goods. This is achieved by carefully adjusting the several key mixing parameters according to the compound requirements while carefully considering chemical interactions of ingredients. Each rubber compound performs and reacts differently to the process. Therefore , to create a ideal mixture ,it requires an experienced operator execute on each compound’s detailed and exact mixing procedure .

Key Components of a Rubber Kneader

*Mixing Chamber: The mixing chamber is a critical part of this laboratory dispersion kneader, which directly impact mixing efficiency and product quality. The mixing chambers of our laboratory kneader machine is made from wear-resistant alloy steel materials, which is duly polished and hard chrome plated, adding a best service life to the kneding machine with an adjustable tilting angle (max. 140) for easy discharge.

*Rotor Design: Made of alloy cast-steel, spirally annular design, which is crucial for effective kneading . We offer various designs, including interlocking and meshing types, to meet different material and process requirements. Interlocking rotors provide efficient mixing for general rubber; meshing rotors are ideal for applications needing higher mixing uniformity, such as high-filler rubber.

*PRESSURE LID: Steel fabricated hard faced at mixing contact area, Jacketed for effective heating / cooling.

DUST SEALS: Specially designed to keep environment Cleanliness & are easily replaceable.

*Control System: Available in Manual push button electrical control or Automatic by electrical Control panel with P.L.C (Programmable Logic Controller) as per clients’ requirements. The PLC systems, allows users to set and monitor temperature, pressure, and time via a touch screen.

Safety Feature

*Emergency brakes with limit switch

*Emergency brakes Chest bar with reverse INCH facility provided

*Emergency brakes Provided on both sides to stop machine in ⅓rd Revolution of Front Roll

*Auto reversible control panel

*Hydraulic & Electromagnetic Thruster Brakes

Applications of Rubber Kneaders

*Tire Manufacturing: In tire production, the laboratory dispersion kneaders are essential for mixing natural or synthetic rubber with various additives, such as fillers, plasticizers, and vulcanizing agents. Our equipment precisely controls temperature and pressure during kneading, enhancing tire grip and wear resistance.

*Rubber Product Compounding: Dispersion kneaders are widely used to produce rubber compounds like sealants, silicone rubber ,gaskets, hoses, and conveyor belts. Efficient mixing and material distribution enhance the physical properties of rubber, such as strength, elasticity, and chemical resistance, making our equipment suitable for the automotive, aerospace, and construction industries.

*Polymer and Chemical Processing: In the polymer and chemical industries, this laboratory dispersion kneader produce rubber and plastic products such as films, sheets, adhesives, and Pharmaceutical industry.

Benefit of Simptek Kneader

* Enhanced productivity : Increase your production efficiency with this high-capacity kneader, reducing processing time and enhancing overall output.

* Consistent Quality : Achieve unparalleled consistency in rubber compounds ,satisfying the most stringent quality standards with every batch.

* Versatility : Suitable for a wide range of rubber formulations and applications , also applied for diverse industry needs .

* Reliable Performance : Experience reliable and precise mixing ,ensuring uniform dispersion and superior product quality .

Reviews

There are no reviews yet.