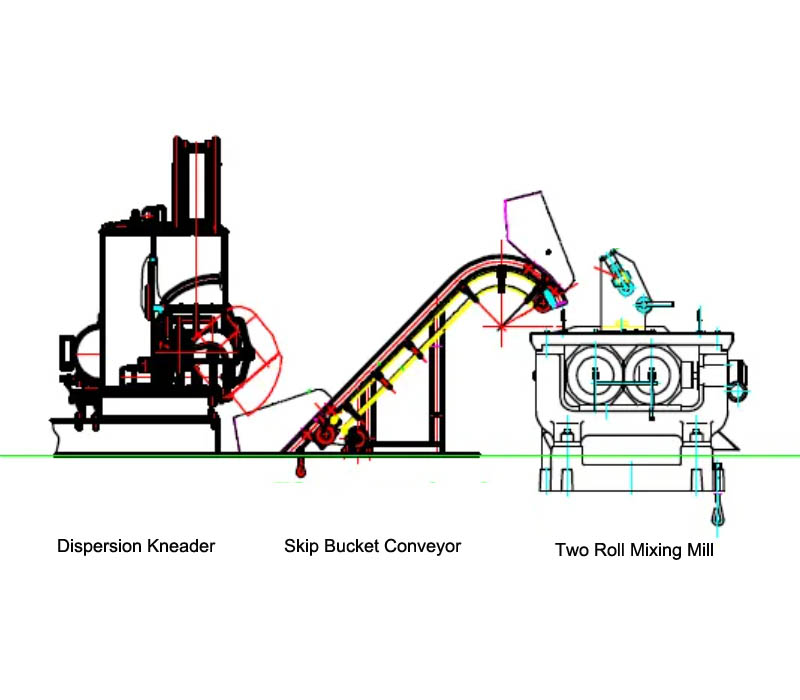

Description

Rubber dispersion kneader are also known as banbury intensive mixer , specially used for mixing and blending rubber and plastic materials for mastication master . it is suitable for mixing and dispersion of carbon and numerous of raw material,ranging from low viscosity adhesives to high viscosity rubber,including rubber ,PVC,plastic,chemical,EVA, TPR etc Simptek Intensive mixer boasts the possibility of integration with a cermet lining.

Due to this feature ,our machine bestows prolonged operational resilience even in the face of the most abrasive raw materials, thus withstanding the harshest operational conditions. The vessel’s interior surface can be sheathed in a variety of steel types or other specialized materials. This banbury intensive mixers are a type of internal batch mixer used in a range of industries ,including rubber ,plastic,chemical ,silicone,EVA ,color master batch , they are applicable for Rubber, Rubber sole, Rubber Roller, EVA,TPR,Hoses Belts, Sponges, Vibration Insulator, Elastic Cord, Sealing Materials, Tire, Tapes, Master Batches, Pigment Ink, Automobile Electric Rubber Parts, Chemical Industry Compounds etc.

Banbury Mixer: The Benchmark of Rubber Mixing Our Banbury mixers are the industry standard for high-capacity rubber mixing. They blend raw rubber with various ingredients efficiently, ensuring a high-quality compound. With precise control over temperature, pressure, and mixing time, they are ideal for large-scale production.

Kneader Mixer: Versatility and Precision The Kneader mixer is perfect for smaller batches and specialized rubber compounds. With intermeshing blades, it provides thorough mixing and excellent dispersion of ingredients. Its flexibility allows for precise control, ideal for custom formulations. Excellent Serve When you invest in an Simptek machine, you’re not just buying a product — you’re partnering with a team dedicated to your productivity and performance. When you invest in an Simptek machine, you’re not just buying a product — you’re partnering with a team dedicated to your productivity and performance.

We have cultivated the best Service & Retrofit team in our industry. Our technicians are exhaustively trained in structural, hydraulic, electrical, and controls technologies to ensure your production machinery continues running long into the future.

From spare parts to preventive maintenance, our services ensure the optimal operation of your products and support you throughout the entire life cycle of your machines and equipment. Your needs are the focus of our thoughts and actions: individual, qualified and comprehensive Technical Support, Calibrations, Preventative.

This valuable training can be tailored to best meet your needs. Preventative Maintenance (PM) service and calibration services available.

Please feel free to contact us at sales@mixingmill.com or Tel at 86-15976867748 to request a quotation. Our committed Service Team will help to guide you through adding individual replacement components and/or complete retrofits for your existing equipment, along with any technical questions you may have.

Material Construction Of Dispersion Kneader Banbury Mixer

* MIXING CHAMBER : Alloy Steel, Fabricated Hard faced, jacketted (both logitudinal & transverse) for steam heating & water cooling. Capable of Tilting to Approx, 140° for eay discharge & cleaning.

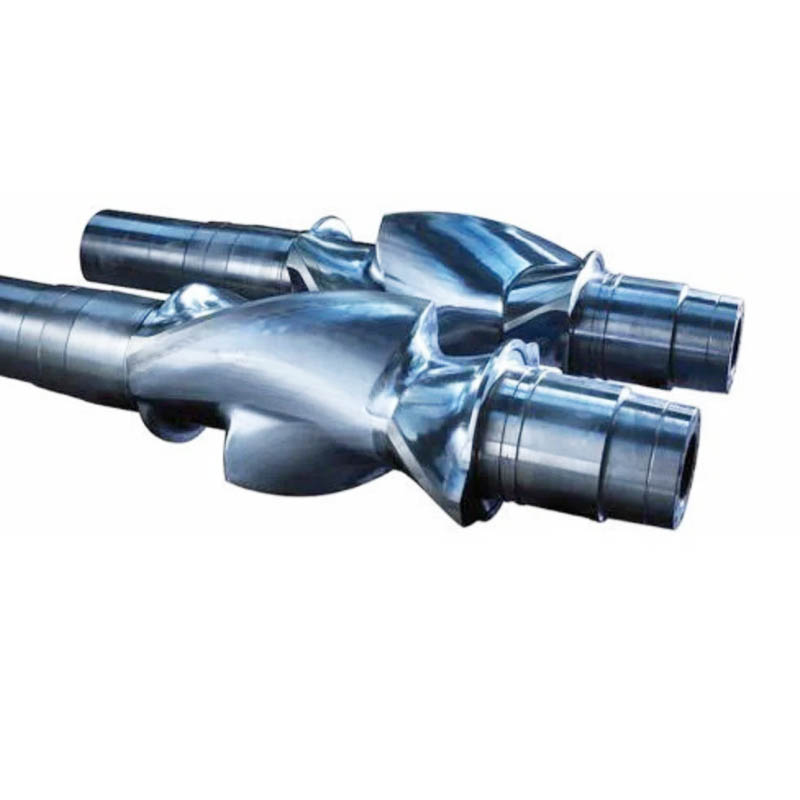

* MIXING ROTORS: Made of alloy cast-steel, spirally anullar design, with node tips i nternally cored for effective Tempretaure Control.The Land of the nodes are hard & profile ground.

* PRESSURE LID: Steel fabricated hard faced at mixing contact area, Jacketted for effective heating / cooling.

* DUST SEALS: Specially wet / dry type designed to keep environment Cleanliness & are easily replaceable.

* DUST EXHAUSTING DEVICE: Hovering Vapours / dust, absorbed by ducting to dust collector.Tilting to Approx, 130° for eay discharge & cleaning

Specification of Dispersion Kneader Machine

| Mode | SMP-35HD | SMP-55HD | SMP-75HD | SMP-110HD | SMP-150HD |

| Mixing Capacity(L) | 35 | 55 | 75 | 110 | 150 |

| Main motor horse power (HP) | 50-70 | 75-100 | 125-150 | 150-200 | 200-300 |

| Tilting motor (HP) | 3 | 5 | 5 | 5 | 7 1/2 |

| Air compressor (HP) | 5 | 7 1/2 | 7 1/2 | 7 1/2 | 7 1/2 |

| Exhaust fan | 1 | 1 | 1 | 1 | 1 |

| Material feed | BACK | BACK | BACK | BACK | BACK |

| Temp control | AUTOMATIC | AUTOMATIC | AUTOMATIC | AUTOMATIC | AUTOMATIC |

| Control panel position | BACK | BACK | BACK | BACK | BACK |

| Rotors revolution | 30/25 | 30/25 | 30/25 | 30/25 | 30/25 |

| Normal air pressure | 6-7kg/cm2 | 6-7kg/cm2 | 6-7kg/cm2 | 7-8kg/cm2 | 7-8kg/cm2 |

| Outline Dimesion m/m(for reference) | |||||

| H | 2,890 | 3,076 | 3,150 | 3,600 | 4,100 |

| W | 1,800 | 2,130 | 2,400 | 2,490 | 3,050 |

| L | 3,669 | 4,010 | 4,200 | 4,930 | 5,480 |

Optional Features

1. Temperature Control:

– Heating and cooling systems for temperature control

– Thermocouple or temperature sensor for monitoring

2. Automated Systems:

– Automated feeding and discharge systems

Maintenance Services & Repair Resources Include

Online video or telephone serve , support and technical assistance.

* Phone, fax or email support of your in house maintenance staff.

* Preventative Maintenance (PM) and calibration services available.

* On-site training or start-up assistance available.

* A regular calibration and maintenance schedule can ensure reliable, efficient operation of your press equipment and identify problems before they cause costly downtime.

Part Repair Service Recondition your worn out rubber parts economically with our remanufacturing service. Parts are remolded and meet original specifications while saving time and cost. Secondary Operations Complete inclusive services provide you quality, finished parts for your production demands. Flashtrimming, inspection, component assembly and packaging are some of the service capabilities available on any custom molded part.

Operator Training Program We offer in-plant training to your operators. Our technicians know the industry, and especially, our production machinery.

The Benefits Of Automatic Dispersion Kneader Machine

* Enhanced productivity : Increase your production efficiency with this high-capacity kneader, reducing processing time and enhancing overall output.

* Consistent Quality :Achieve unparalleled consistency in rubber compounds ,satisfying the most stringent quality standards with every batch.

* Versatility : Suitable for a wide range of rubber formulations and applications , also applied for diverse industry needs .

* Reliable Performance : Experience reliable and precise mixing ,ensuring uniform dispersion and superior product quality .

Application of Dispersion Kneader Machine

Tire Manufacturing: In tire production, rubber dispersion kneaders are essential for mixing rubber material ,including natural and synthetic rubber with chemical additives. This ensures the final product has excellent physical properties and durability.

Rubber Product Compounding: These rubber dispersion kneaders machine are widely used to produce rubber compounds like seals, gaskets, hoses, and conveyor belts. Efficient mixing and material distribution enhance the physical properties of rubber, such as strength, elasticity, and chemical resistance, making our equipment suitable for the automotive components ,seals , aerospace, and construction industries.

Polymer and Chemical Processing: In the polymer and chemical industries, the rubber kneaders equipment are used to produce rubber and plastic products such as films, sheets, adhesives, and medical devices. Their efficient kneading ensures uniformity and consistency in polymer materials, improving product quality. In medical device production, they mix high-purity materials to meet strict hygiene standards.

Advange We Offer

Our in-house made screws and barrels are controlled and tuned with scrutiny and the recision at the szie of 0.3mm. It enables the perfect mechanical intermesh and ensures continuous smooth operation

Despite of the part or material may wear out after some time , but nearly all of the simptek made equipment are still running even for 20 years and making profits for our clients since the begining.

- Human/Operator Safety

- Motor & Drive Safety

- Gearbox Safety

- Precise and Accurate Process Control

- Sustainability

- Superior Plastication

- Stability

- Better Mixing Effect

Delivery for Free Tool

Reviews

There are no reviews yet.