Description

The two-roll rubber mill is a mixing processing machine used to process rubber (natural or synthetic) into various compounds material,this mixing machine mainly comprises two rolls, metal frames, beds, bushings, bushing lubrication, roll gap adjustments etc.

The two rolls are made of vanadium titanium metal alloy chilled cast iron, whose surface is hard and wear-proof, and its hardness can reach up to 65-70HS. These hollow rolls adopt double auto-centring rolling bearings lubricated by lubrication grease. The rolls rotate in opposite directions at different speeds; usually, the rear rolls have a higher speed than the front rolls. They mix and knead the raw material uniform and get the ideal compound material. The rear roll usually has a higher speed than the front roll. This allows for the proper mixing and kneading of the raw materials into high-quality compounds and is ideal in use.

The laboratory rubber mixing mill machine is equipped with an emergency brake device. Users can immediately draw the safety pull rod or press the emergency button, and the machine will stop immediately to guarantee the operator’s safety.

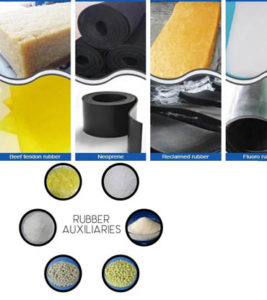

Our rubber mixing mill machine is used for mixing and kneading raw rubber, synthetic rubber, thermoplastics, hot melt adhesive, chemical medicine or E.V.A with chemicals into final materials ,they are available in various sizes ranging from 3, 4, 5, and 7 inches.

Mixing mills offer high tech machinery that comes with many features that will provide long life and precise material control. In the end ,the final compound materials would be fed to a calender machine, hot presses or other processing machines for making rubber or plastic products.

If you are looking for high tech two roll mixing machines, under-budgeted rates count on mixingmill.com.

Jhon Attack –

We’re a financial and consulting business company of professional thinkers, strategists, digital innovators, designers and problem solvers (everyone gets a mention). Our sense of curiosity brings thinkers, strategists, digital innovators, designers and problem solvers (everyone gets a mention).