Description

Mini Economical Small Product Weighing Compact Touch Screen Check Weigher is a type of weighing machine designed for the purpose of checking the weight of individual products or packages within a production or packaging line. Mini Check Weigher are vital for quality control, ensuring products meet specific weight standards.Welcome to consult for quotation information!

This smark mini weigh checker machine is mainly used for connecting with vertical packaging machine to check the weight of finished packing products and sort the incorrect items promptly..

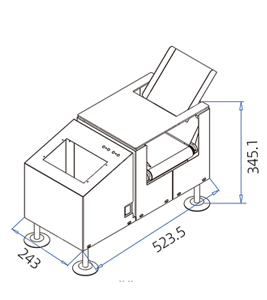

Parameter details :

|

Model

|

Mini Automatic Checkweigher Check Weigher Scale

|

|

Power Supply

|

220V(AC) 50Hz

|

|

Weighing Accuracy:

|

±0.2g(can identify materials with a single weight of 0.3 g and above 0.3 g)

|

|

Belt Speed

|

0-50m/min

|

|

Speed

|

4000pcs/H

|

|

Product size

|

L200mm*W150mm

|

|

Display

|

7-inch highlight touch screen

|

|

Maximum weighing

|

200g

|

|

Weighing conveyor belt

|

L250mm*W168mm

|

|

Inlet height

|

420±30mm

|

|

Scale platform height

|

230±30mm

|

|

Weighing Accuracy:

|

±0.2g(can identify materials with a single weight of 0.3 g and above 0.3 g)

|

|

Belt Speed

|

0-50m/min

|

|

Speed

|

4000pcs/H

|

|

Product size

|

L200mm*W150mm

|

|

Display

|

7-inch highlight touch screen

|

|

Maximum weighing

|

200g

|

|

Weighing conveyor belt

|

L250mm*W168mm

|

|

Inlet height

|

420±30mm

|

|

Scale platform height

|

230±30mm

|

Reviews

There are no reviews yet.