Description

This manual table press vulcanizer machine features compact size but has complete functions for vulcanizing rubber mateiral ,it is applicable to R & D in laboratory.

Vulcanizing press machine is also known as Lab curing press equipment ,it is one laboratory equipment, applicable to R & D in laboratory,used to make all kinds of vulcanizing mould,rubber products,plastics products,and testing pieces used by institute, university & college.

This laboratory vulcanizing press machine is one equipment used for vulcanizing various rubber and plastic products, it heat rubber material with sulphur ,accelerator .

The lab hydraulic press machine has two independent heating platen and a manual oil cylinder pump ,which is used to make the heating plates clamp. Such laboratory manual hydraulic press machine can be used for sample preparation, color-matching plate, or flattening specimens, it is very convenient for factories to produce materials accordingly.

The vulcanizing press machine is mainly used to compress the plastic silicone rubber material into a sheet or to complete the curing of rubber mixture for subsequent texting .This laboratory press machine has been developed to hot vulcanize all types of rubber, plastic, silicone etc material, including EPDM, NBR, SBR CR, NR, polymer etc .

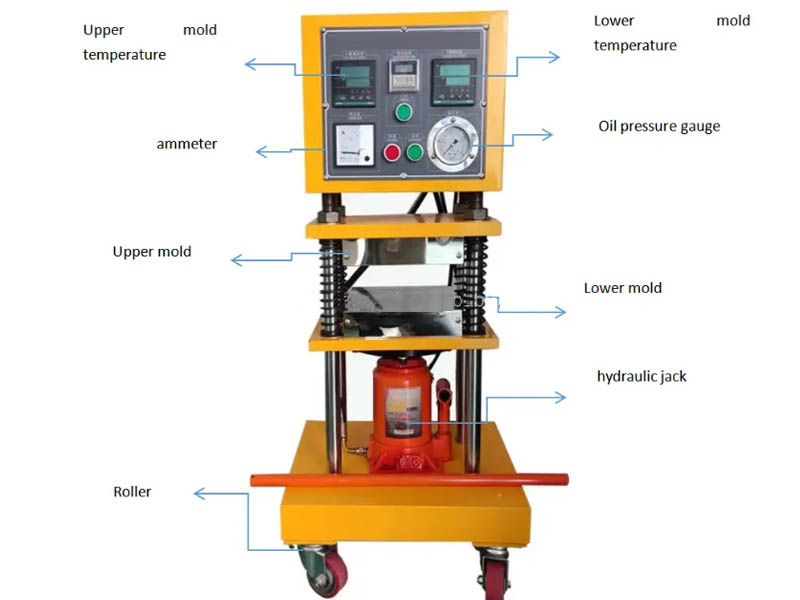

Our hand-operated compression molding press machine is a vertical structure ,it come with 4 guide columns and a horizontal platform forming a stable frame .The two pressure plates are made of rugged SKD mold steel material ,whose surface is chrome plated and polished ,in order to keep the feature of excellent parallelism , high hardness ,exceptional wear and corrosion resistance . The upper pressure plate is fixed while the lower plate arranged longitudinally in parallel ,which can move vertically up and down , driven by the hydraulic ram when being operated .

The half-automatic hydraulic press machine also are built-in hearing tubes inside these two pressure plates ,so that ensure a uniform temperature when the maching is working . This laboratory can be heated the temperature up to 300 degrees Celsius.

At Simptek ,we tailored and supply a variety of hydraulic press vulcanizing machine ,the capacity range from 10 Ton to 500 ton as per your specific needs .

Feature:

| Capacity | 20T,25T ,30T |

| Temperature Range | R.T.~300°C |

| Temperature Controller | LED digital display, key setting input, numerical display output |

| Temp Accuracy | ±2℃ |

| Heating Method | Cartridge Heaters |

| Warm-Up Time | 0 ~ 200 ° C takes about 25 min |

| Timer | LED digital display 0.1S ~ 99M~ 9.9h curing time can set the alarm |

| Press Platen Dimensions | 350×350×40mm,customized |

| Press Layers | Single layer, heating up and down mould pressing plate |

| Clamp Distance | 60mm |

| Pressure Gauge | 0~350kg/cm2 |

| Working Power | 4KW |

| Dimension | 400x450x1000(W×D×H)mm |

| Weight | 195kg |

| Power Supply | 1∮,220V,15A(Customer prepare power connection) |

What Is Vulcanized Rubber Used For?

Vulcanization gives rubber its characteristic more elastic and durable quality ,it is vital for rubber,silicone,plastic polymer industries . the vulcanized rubber material can be used to produce many products ,including soles of shoes, hoses, hockey pucks, bowling balls, toys, tires, bouncing balls, and much more.

How Do Vulcanizing Press Work?

Vulcanisation is a thermochemical process which is vital for rubber industries. The rubber vulcanization includes a series of complicated chemical reactions with sulfur,accelerators and additives,it promotes cross-linking between rubber molecules , in order to improve the strength, abrasion, and aging resistance of the rubber. The vulcanized rubber material become more flexible ,elastic and durable than rubber that has not been vulcanised.

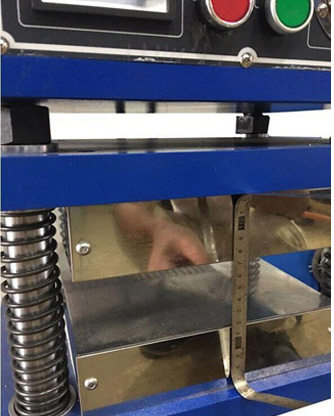

On the process of vulcanization , the rubber material are placed between two flat heated to a specified temperature . After high temperature and high pressure ,the rubber vulcanization is pressed into the desired shape . Here is the process of vulcanization as follows:

1. Pre-treament for Material :the rubber material to be vulcanized needs to be pre-treated, for example the material should undergo these process ,such as rubber cutting, crushing & blending, and mixing & kneading.

2. Charging and Loading Mold :the material treadted are sent to the rubber vulcanizer equipment for curing .The material are usually mixed with additives such as vulcanizing agents, accelerators, preservatives, and fillers to form a uniform rubber mixture.

3. Setting Heating & Pressure :Set some certain temperature and pressure ,process time for the vulcanization machine,which are controlled by PLC system .

Basically ,the vulcanization temperature can be adjustable as per different rubber materials and vulcanization requirements ()between usually between 140°–180° ). The vulcanization time is usually longer and can last from a few minutes to several hours.

4. Cooling and Curing: When the vulcanization reaction is completed, the hydraulic vulcanizing press machine starts the cooling system to cool the vulcanized rubber products, to cure their shape and structure.

Application of Vulcanization

The vulcanized rubber material feature higher tensile strength and thermal stability and durability ,it is 10 times more stronger than natural rubber. The vulcanized rubber material can be widely used to produce many products ,including

Shoe soles

Bowling balls

Motor mounts

Suction cups

Rubber Seals

Rubber O-rings

Conveyor Belts

Sealing Seal

Medical Silicone Products

Sports Equipment

Toys

Erasers

Hockey Pucks

Shock absorbers

conjugate fiber

silver solder

indium powder

carbon black powder

thermoplastic

thermosetting plastics

polytetrafluoroethylene

ceramic material

metal bonded sample

Reviews

There are no reviews yet.