Laboratory kneaders are widely used in rubber, silicone,chemical , ceramics, polymers, plastic , adhesives, batteries, food ingredients , pharmaceuticals etc. While most people focus on the kneader’s capacity, power, and control system, there is one critical component neglected but it determines the mixing efficiency, shear force and material dispersion and final product quality. That is blade style inside the mixing chamber .

In order to satisfy the need for different material processing, manufacturers usually offer several kinds of blade styles with unique structural designs and its working principles.

So why the rotating blade is so important ?

In this blog, let us explore the most common kneader blade styles, their features, and best applications.

Common Rotating Blade Styles and Their Applications

Different lab kneader models are equipped with specific blade designs to handle different material characteristics

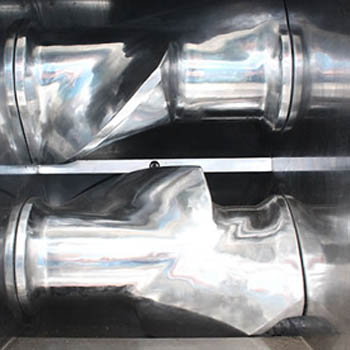

1. Sigma Blade (Σ Blade) — High Shear, Powerful Kneading

The Sigma blade is the most classic and widely used kneader blade , it adopt two tangentially rotating Σ-shaped blades used for kneading, stretching, and squeezeing material, achieving a thorough and homogeneous mixture for demanding applications in various industries,

This designed blade is specially handling high-viscosity compound material up to 10 million centipoise, like adhesives, silicones, rubbers, pastes, putties, , carbon pastes, cosmetics, food, PVC compounds and construction.

2. Spiral Blade — Gentle Mixing, Fast Circulation

The spiral blade is designed smooth and helical profile resembling a twisted ribbon. this spiral bade is mainly used to produce a forward-pushing flow, ensuring continuous material circulation.

Compared to sigma blade ,this spiral blade provides lower shear force,

it promotes continuous circulation and encourages faster material turnover , reducing mixing time.

The spiral blade is suitable for delicate formulations that cannot withstand excessive compression ,it is very ideal for ceramic pastes, battery electrode slurries, food compounds, pharmaceutical dough and soft polymer formulations etc.

3. Z-Blade — Versatile, Balanced Mixing

Features: Balanced shear, suitable for various viscosities.

As its name ,this blade is designed as “Z” shape, which combines elements of both sigma and spiral blades.

Best For: General-purpose adhesives, silicone compounds, polymer blends.

Both arms rotate towards each other, creating a balanced shearing effect.

This “Z” shape blade offers moderate shear to ensures even dispersion without over-processing,it is suitable for both solid-to-liquid mixing and liquid-to-liquid blending, ideal for a wide range of viscosities, from low-to-medium viscosity adhesives ,including sealants & caulks and polymer blending etc.

4. Masticator Blade — For Rubber Bale Breaking

The masticator blade is designed to tear and stretch materials , usually thick and aggressive arms.

Due to the rotating action ,which generate high shearing, strong tearing and stretching for intensive mixing to the compound material , thus it ensures uniform filler dispersion in rubber formulations , very ideal for breaking down natural and synthetic rubber bales. Such designed blade is suitable for tire rubber, EPDM seals, silicone elastomers and High-strength elastomers etc

5. Specially Tailored for Customized Blades

Except these common blade types as mentioned above, Simptek Machine also can provide custom-designed blades to meet special processing needs, including as follows:

* Vacuum-resistant spiral blades for ceramics & battery slurries

* Cooling-jacket compatible blades for exothermic reactions

* Anti-stick coatings for adhesive and gum mixing

* PTFE-lined blades for pharmaceutical and food applications

3. How to Choose the Most Suitable Rotating Blade

Since the kneader’s blade is so important ,so how to chose the most suitable rotating blade ? Before you chosing the right blade ,you need to consider 3 key factors as follows:

Step 1 — Consider the Material’s Viscosity

| Material Type | Recommended Blade | Reason |

| High-viscosity compounds | Sigma or Masticator blade | Provides powerful kneading and compression. |

| Medium-viscosity pastes | Z-blade or Double Spiral | Ensures uniform dispersion. |

| Low-viscosity slurries | Spiral blade | Allows gentle yet efficient circulation. |

Step 2 — What is the Mixing Objective

If you want to break down solid particles ,then chose sigma or masticator blades

If you want fast, uniform dispersion ,then chose double spiral blades

If you want delicate, heat-sensitive formulations ,then chose spiral blades

If you want multi-purpose lab testing or formulation purpose ,then chose Z-blades

Step 3 — Match Blade Speed and Torque

High-torque blades ,like Sigma or Masticator blade are ideal for dense, sticky, and rubber-based compounds.

While these medium-speed blades ,like Z-blades, Double Spiral blade are ideal for balanced applications.

As to fast-turnover blades ,such as spiral blade ,it can reduce cycle times for lightweight materials.

In conclusion ,the rotating blade is one of the most critical components of a lab kneader , it determines how effectively, quickly, and consistently your material can be processed, it determines the quality of your final mixture.

Therefore , If your material is thick and sticky, choose Sigma or Masticator blades.

For gentle, uniform mixing, go for Spiral or Double Spiral blades.

If you want to process for multi material, then chose Z-blades ,it may be the best opition for you.

At Simptek , we can custom and provide various rotating blade for lab kneaders for your different industries and materials needs.