When it comes to the structure of a lab dispersion kneader, one of the most crucial components is the blade style.

Its design determines how materials are kneaded, how quickly they reach homogeneity, and how well they are dispersed.

The type of disperse blades directly influences the kneader’s mixing efficiency, dispersing process, and material processing compatibility.

In this blog, we will talk about the main types of blades widely used in lab-scale kneaders and explain its specific function.

Why the Blade Matters in Lab Knead Machine

Whether you are mixing high-viscosity rubber ,chemical or soft thermoplastics, plastic etc , the blade style determine how effectively ingredients are blended.

The blade of a lab kneader defines the performance of the kneader mixer. It effect many factors , including : Mixing intensity,Shear force applied,Material flow pattern,Mixing time and consistency ,Final dispersion quality and so on.

Type of Blade of Lab Kneader:

1. Sigma Blades – For Intensive Mixing

Design & Function: Sigma blades are one of the most commonly used “Σ” desired blade types in lab kneader machines. Due to their powerful shearing and folding action which makes such sigma blades are very ideal for mixing viscous materials like rubber compounds, silicone, and polymers.

The “Σ” Design Blade Are Suitable For Various Industries ,For Example:

* High-viscosity elastomers

* Rubber masterbatch formulation

* Plastisol and sealant materials

* Thermosetting resins

* Chemical

* Color Masterbatch

* Sealant

Advantages of “Σ” Design Blade :

* Excellent shear mixing

* Efficient kneading in small batches

* Ensures uniform distribution of additives

2. Z-Blades Suitable for Kneading and Shear

The Z-shaped blades are designed to offer a balance between kneading and shearing. They produce a gentle but effective blend force, which are ideal for medium-viscosity materials .

The Z Design Blade Are Suitable For:

* Heat-sensitive materials

* Color masterbatches

* Food and pharma-grade compounds

* PVC pastes and TPE formulations

Advantages of Z Design Blade:

* Gentle on sensitive materials

* Lower heat generation

* Uniform dispersion with minimal degradation

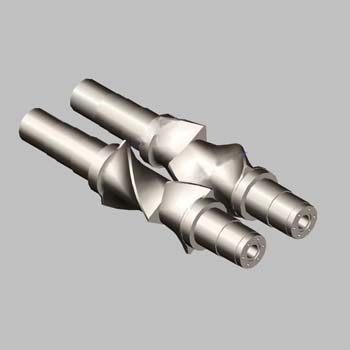

3. Double-Screw (Co-Rotating) Blades – For Complex Dispersing Mixes

Design & Function: Some advanced lab kneaders adopt co-rotating double blades that mimic twin-screw extruders. Such co-rotating designed blade offer simultaneous mixing and conveying, which is ideal for research labs processing complex reactive blends.

The Double Screw Blade Are Suitable For These Industries:

* Reactive or multi-phase systems

* Filled composites

* Polymer blending with in-situ reactions

Advantages of Double Screw Blade :

* Continuous mixing and transfer

* Excellent distribution of multiple phases

* Compact batch process simulation

There Are So Many Kinds of Blade ,So

How to Choose the Right Blade for Your Lab Kneader?

Actually ,before you chose one blade for your laboratory dispersion kneader ,you need to consider several factors as follows:

* Material viscosity

* Heat sensitivity

* Desired shear force

* Thermal sensitivity

* Batch volume and rotation speed

* Mixing uniformity and dispersion quality

Each blade type brings unique mechanical action and energy transfer characteristics. As to the best design blade depends on your formulation goals and material of your products.

Thus , for manufacturers or research labs from University who are looking to improve their formulation process, a well-chosen blade for lab kneader would offer you the best mixing results for the material systems.

Whether you are working with tough rubber batches, delicate pharmaceutical pastes, or thermoplastics, chosing the right kneading blade is crucial to performance, repeatability, and product quality.

If you have any question on the lab kneader at Simptek ,welcome to talk with our experts .