In polymer chemical material Industries today, it requires more and more demand efficient, reliable, and high-performance advanced mixing and discharge solutions to process high-viscosity materials, such as silicone, adhesives, rubber compounds,sealant, chewing gum, printing inks, chewing gum, ceramic pastes, high-density polymers and putties, certain glues, bitumenetc. These high-viscosity materials are sticky, dense, and a little difficult to handle if still adopt conventional mixing equipment.

A stainless steel sigma kneader with extruder combines strong powerful mixing capability of a sigma kneader mixer with the efficiency of an extrusion system, it provides a seamless solution for producing uniform, high-quality products.

1. What is a Stainless Steel Sigma Kneader with Extruder?

A stainless steel sigma kneader equipment made of high quality stainless steel (available in SUS314, SUS316), it is a heavy-duty mixing machine which is equipped with two counter-rotating sigma-shaped blades .

A stainless steel sigma kneader with extruder offers the perfect solution by combining intensive mixing power with continuous automated discharge.

With two sigma blades are specially designed to knead, mix, and homogenize high-viscous compounds material . When this sigma kneader machine are integrated with an extruder, the polymer blending kneader would not only mix and knead the compound material thoroughly , but also it continuously discharges the material without manual interference.

2. Why Use Stainless Steel for High-Viscosity Applications?

Basically the high-viscosity materials like chemically material are high dense, a little sticky, and sometimes even a little aggressive. Thus the construction of material is very critical .

When you choose a wrong material , it can lead to damage to your expensive equipment , production downtime, and product pollution.

That is why stainless steel sigma kneaders are becoming the best choice in these industries which demand high quality, reliability, and product safety.

As choosing the right construction material Industrial sigma kneader can ensure several advantage as follows:

* Corrosion resistance → Perfect for adhesives, chemicals, and sealants

* Hygienic and easy-to-clean surface → Essential for food, pharma, and medical applications

* Durable and wear-resistant → Capbable to handle high-viscosity abrasive and sticky materials

* Compatible with vacuum and pressure systems → Vacuum removes trapped air and moisture for better texture and shelf life, improving product consistency and ensuring contamination-free mixing

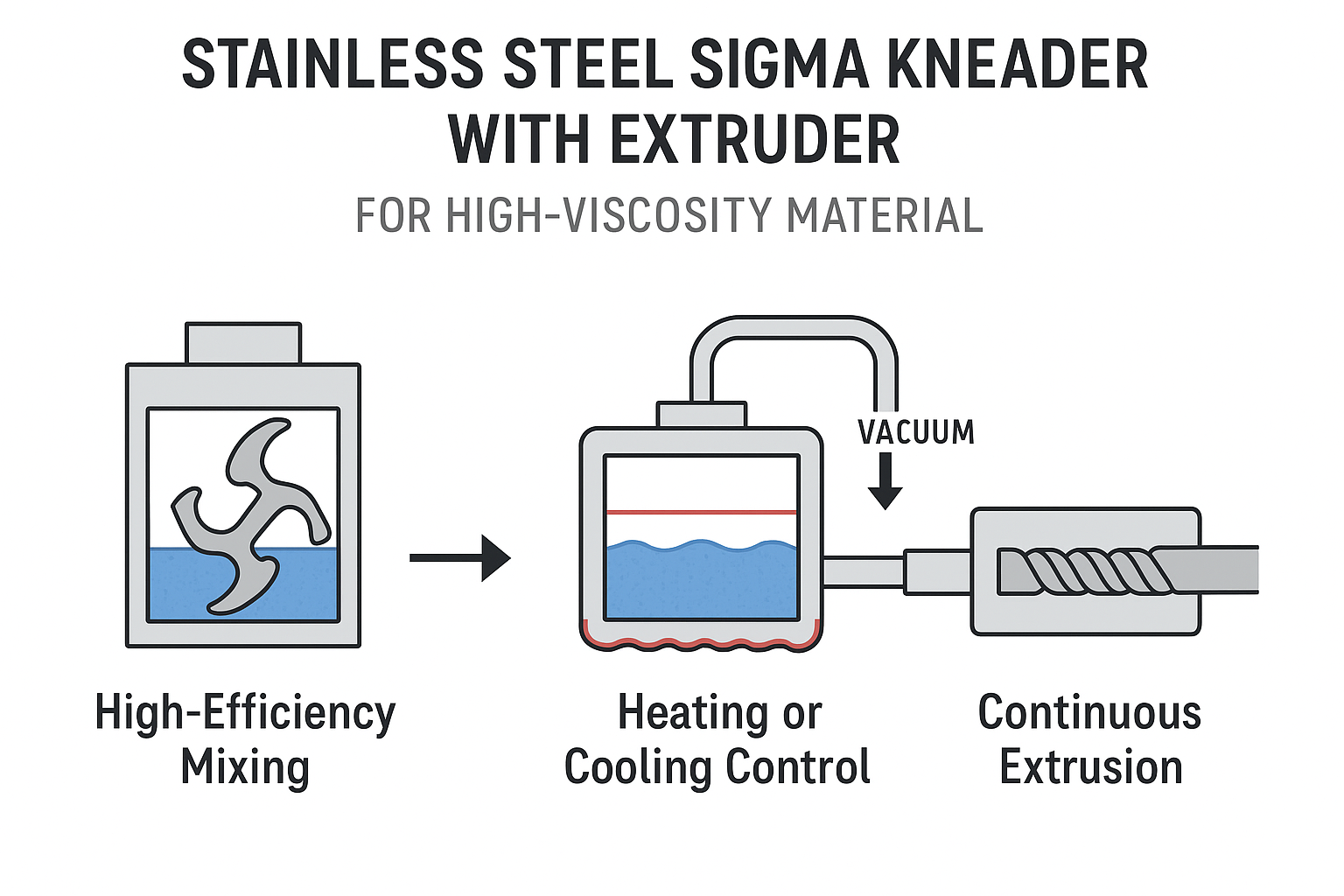

3. How Does Sigma Kneader with Extruder Works

Step 1 — High-Efficiency Mixing

The two sigma-shaped blades of the sigma kneader for adhesives rotate at different speeds in opposite directions , generating intense shearing and kneading action . The powful force fold , stretch and knead the high-viscosity compound material against the trough walls and a central saddle to achieve a perfect blend.

Step 2 — Heating or Cooling Control

The jacketed chamber of sigma kneader allows temperature adjustment by way of heated water, oil, or steam, which is great to maintain the material’s desired viscosity during processing.

Step 3 — Vacuum Equipped

For these material such as polymer silicone sealants or pharmaceutical compounds, a jacketed vacuum sigma kneader can

be added with vacuum system ,so that meet higher requirement for special material and remove air bubbles on the process.

Step 4 — Continuous Extrusion

The continuous extrusion of this jacketed vacuum sigma kneader adopt a discharge screw to push, mix, and extrude the homogenized compound material automatically through a discharge port of the sigma kneader for rubber compounding at the end of the process.

Here The Visual Process Flow Diagram Showing How Kneading + Extrusion Works:

4. Applications of Stainless Steel Sigma Kneader with Extruder

The silicone sealant mixing sigma kneader is widely used in a variety of industries which require intensive mixing and efficient discharge, such as :

* Silicone Sealants & RTV Compounds

* Hot Melt Adhesives

* High-Viscosity Printing Inks

* Polymer Blends & Compounds

* Chewing Gum & Confectionery

* Ceramic Pastes & High-Density Pigments

* Rubber-Based Compounds

Here , you can learn its advantage of stainless steel sigma mixer

Through the way of combining kneading + extrusion, manufacturers can significantly increase products capacity maintaining consistency and quality. ,at the same time greatly reduce production time.

In conclusion , a stainless steel sigma kneader with extruder is the ideal choice for industries which are in the high-viscosity materials. By combining efficient mixing with automated continuous extrusion, it helps manufacturers increase productivity, maintain product.

At Simptek , we specialize in custom-built stainless steel sigma kneaders with extruder . We offer different material selection tailored to your application needs, whether for industrial adhesives, food gums, pharmaceutical polymers, or specialty chemicals.