In the polymer and rubber industry— no matter you make plastics, elastomers, composites, or specialty resins— it is very curcial t o choose a right mixing machine , as it directly affects product consistence, production efficiency and cost . That is why sigma mixer used for . Sigma blade kneader machines as one of the […]

In modern manufacturing industries ,for much time ,we are faced with the high-viscosity (with viscosities ranging from 200,000 cps up to 1,000,000 cps) material, such as rubber, silicone, adhesives, sealants, and high-performance polymers, to handle in these high-viscosity materials is really unavoidable and challenging. Since these high-viscosity material are heavy compound material ,they are very […]

In modern laboratories, mixing process and material testing require compact, efficient, and reliable laboratory equipment . Thus high precision and consistency are very important when testing some material, like polymers, plastic , PVC , rubber compounds, or masterbatches. There are several mixing equipment in variety of size and capacity to process these compound material , […]

Laboratory Mixing mills play a vital role in the rubber,silicone,chemical and plastic industries, especially in compounding, shearing, and thermal mixing. With the market for the demand for precision control and energy efficiency growing, double frequency laboratory mixing mills is developed based on tradition single frequency open mixing mill equipment. But what exactly double frequency open […]

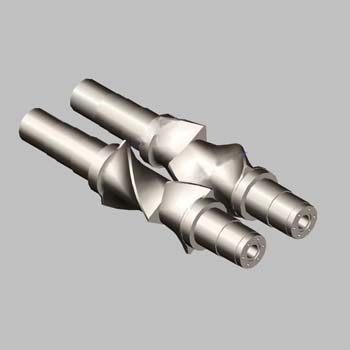

When it comes to the structure of a lab dispersion kneader, one of the most crucial components is the blade style. Its design determines how materials are kneaded, how quickly they reach homogeneity, and how well they are dispersed. The type of disperse blades directly influences the kneader’s mixing efficiency, dispersing process, and material processing […]

In the world of rubber processing, curing process also known as vulcanization, it is a critical chemical process step that transforms raw rubber into a durable, elastic, and resilient material. During vulcanization, cross-links are formed between the polymer chains within the rubber, which result in improved elastic properties over a greater temperature range. Rubber curing […]

In the world of polymer research and development, mixing is one of the most important and complex processes, it is a key and complex process in rubber processing, and its quality affects the quality of the product. The lab two-roll mill equipment play key role in mixing tool—especially when working with PVC (Polyvinyl Chloride) compounds. […]

Laboratory dispersion kneaders ,also called as Lab internal rubber mixer ,they are indeal equipment for research and development and small batch of the latest rubber and plastics material, suitable for mixing, kneading and dispersing various low-viscosity material, including plastics, rubber, synthetic rubber, hot melt adhesive. The lab dispersion kneaders prefectly controls mixing and blending of […]

An open mixing mill also called a two-roll mill, it is are essential equipment widely used in the rubber and plastic industries, including for processing PVC (polyvinyl chloride), color master batch ,polymer etc. Today, open mixing mill equipment are indispensable in plastic rubber industries that require high-volume production of rubber and plastic products, such as […]

In the rubber and plastic industries, precision, consistency, and efficiency are critical factors in product development and manufacturing. In order to mix and masticate raw rubber and synthetic rubbers including NBR, SBR, BR, etc.to improve their dispersion and plasticity ,so that it can be used in the next process ,the most essential equipment in this […]